If the curvature of the tooth is a large radius they can easily be confused with a straight bevel gear. In essence Zerol Bevel Gears are Spiral Bevel Gears with a spiral angle of zero.

What Sets Candy Controls Hypoid Gearbox Apart

Serving customers in the Aerospace and Industrial Markets.

. By nature bevel gear design is highly complex. Allows compact design as no inward thrust force Reference to the figure is produced which causes problems when using spiral Bevel gears. Ad Were A World-Class Gear Manufacturing Company Specializing In Metric Gearing Since 1935.

A zerol bevel gear also has curved teeth but they are not angled in a spiral so the teeth align with the axis. The tooth lead function in the face width direction if unrolled into a plane is a circle. Balanced and superior performance as they combine the features of straight and spiral bevel gears.

The standard included the pertinent data from and superseded the following standards. Zerol bevel gearbox is modeled with the intent of duplicating the features of a straight bevel gear but they are created using a spiral bevel cutting procedure. Unlike straight Bevel gears Zerol Bevel Gears can be ground finished allowing higher.

One is the zerol bevel which is a curved tooth having elements that start and end on the same radial line. The tooth profile is an octoid. The teeth are curved teeth at an angle allowing tooth contact to be gradual and smooth.

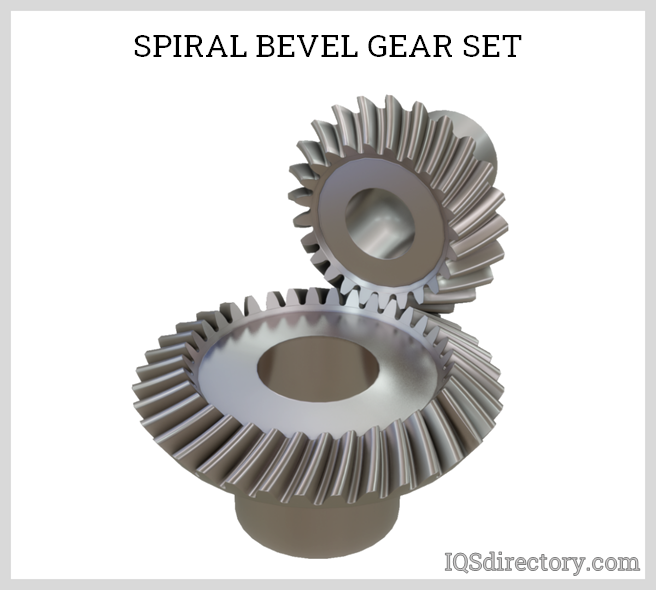

Spiral bevel gears are smoother and quieter in operation than straight bevel gears primarily due to a design that. Covers preliminary gear design parameters blank design including standard taper uniform depth duplex taper and tilted root. Zerol Bevel Gears are spiral Bevel gears with a helix angle of less than 10 degree.

2 Illustration No. Higher Quality Alternative to Straight Bevel Gears. Zerol Bevel Gears are spiral bevel gears but the spiral angle of the teeth is zero.

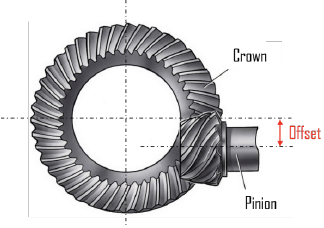

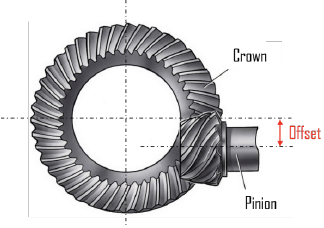

And superior performance as they combine the features of straight and spiral bevel gears. ANSIAGMA 2005-D03 R2008 Design Manual for Bevel Gears Provides the standards for designing straight bevel zerol bevel spiral bevel and hypoid gears along with information on fabrication inspection and mounting. On a hypoid bevel gear the pitch angle is hyperbolic instead of conical and the pinion can be offset either below or above the gear center.

The vast majority of bevel gears are designed for a shaft angle of 90 degrees which we will use for our examples. All Zerol gears have the advantage of localized tooth contact. Zerol bevel gears are the special case of spiral bevel gears with a spiral angle of 0.

ZEROL BEVEL GEARS have curved teeth which are in the same general direction as straight teeth. AGMA 20203 1965System for ZEROL Bevel Gears AGMA 20803 1979System for Straight Bevel Gears. The curved teeth are set at an angle of zero to 10 degrees.

2 They are spiral bevel gears with zero spiral angle and are manufactured on the same machines as spiral bevel. ZerolÆ bevel gears are a special case of spiral bevel gears. They are manufactured in a single-indexing face milling process with large cutter diameters an extra deep tooth profile and tapered tooth depth.

Approximately 200 Styles Of Metric Gearing In More Than 20000 Configurations. Step one in drawing any bevel gear set is to lay out the pinion and gear axes at the desired shaft angle. Spiral bevel gears Figure 5716 have curved oblique teeth that contact each other gradually and smoothly from one end of the tooth to the other meshing with a rolling contact similar to helical gears.

This task was undertaken in 1982 and this revision includes design information for straight bevel spiral bevel and hypoid gearing. Zerol bevel gears are a transitional form between spiral and straight bevel gears. Their teeth have a certain curved shape but are not angled.

Straight bevel gears come in two variations depending upon the fabrication equipment. A reliable source over 50 years for precision Bevel and Parallel Axes Gears. All current Gleason straight bevel generators are of the Coniflex form which gives an almost imperceptible convexity to the tooth surfaces.

Zerol bevel gear teeth follow in the face width direction a curve on the conical gear and pinion body that lies tangential to a cone element zero spiral angle. Allows compact design as no inward thrust force Reference to the figure is produced which causes problems when using spiral Bevel gears. Hypoid bevel gearsThese gears are similar to spiral bevel except that the pitch surfaces are hyperboloids rather than cones.

CALL US 630 543-6640. 1 - Comparison between spiral angles of Spiral Bevel and Zerol Bevel Gears. Precision Gears Per Design Bevel Sets Parallel Axes Gears.

Difference Between Straight Bevel Gear And Spiral Bevel Gear

Bevel Gear What Is It How Does It Work Types Uses

Types Of Bevel Gears And Geometric Calculations With Calculators

Bevel Gear What Is It How Does It Work Types Uses

Bevel Gear What Is It How Does It Work Types Uses

Helical Gear Calculations Crossed Helical Gear Meshes And Bevel Gearing Sdpsi

0 comments

Post a Comment